Brookwood® finishing

A state of the art manufacturing facility that is also a part of history

Market divisions

manufacturing facilities in the USA

. . . and that extra mile we go

Waterproof Breathable

Eco-Friendly Fabrics

Heat Seal Technology

Flame Resistance

roll goods highlights

nylon fabrics : in stock

polyester fabrics : in stock

BROOKWOOD® FINISHING

A state of the art manufacturing facility that is also a part of history

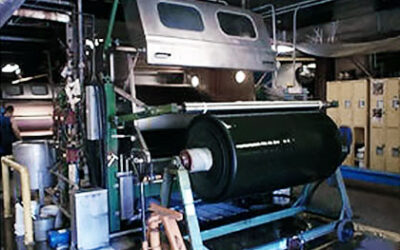

With over 300,000 square feet of cutting-edge fabric processing technology and over seventy-five years of experience, our Brookwood® Finishing facility offers you the highest level of quality coupled with unparalleled experience in dyeing, finishing, coating, and printing of woven synthetic fabrics. Brookwood® Finishing operates three continuous shifts using state-of-the-art finishing equipment, from atmospheric and pressure beams, jigs and jets, continuous dyeing and scouring lines, and solvent and aqueous coating lines, as well as specialized drying and pad finishing frames, all available to impart performance to your fabric.

Brookwood® Finishing also houses unprecedented research and development equipment that reduces the time it takes to create new, complex fabrics from months to days. With certified testing laboratories qualified to test methods recognized worldwide, Brookwood® Finishing is ready to provide you with high-quality fabrics that perform.

capabilities

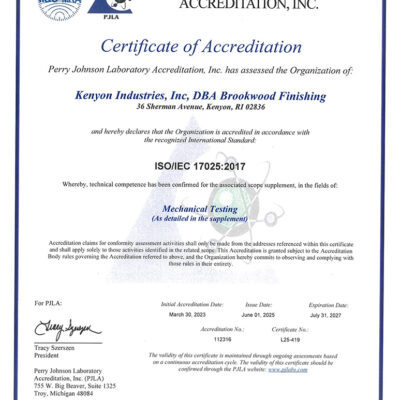

Brookwood Finishing is now ISO/IEC 17025:2017 accredited!

We are proud to share that Brookwood Finishing has achieved ISO/IEC 17025:2017 accreditation, the international laboratories testing and calibration laboratories. This accomplishment demonstrates Brookwood’s ongoing commitment to quality, technical competence, and consistent results.

Earning this accreditation reflects the dedication of Brookwood’s entire team and provides our customers with the confidence that every process meets the highest global standards.

Brookwood® Acquires SWAN Fabrics™

We are pleased to announce that Brookwood® Companies has acquired Swan Fabrics, a high-quality, short-run dyeing and printing facility located in Fall River, Massachusetts.

Brookwood® is excited about adding Swan Fabrics to our ever-growing family and believe that this acquisition will bring new opportunities and continued success.

Brookwood’s 2022 “Jerry” Cook Scholarships

Soliya Lach, daughter of Sovath Lach (Dye Op), graduated from Cranston HS East. Soliya will be attending URI in the fall to study Nursing and plans to further her studies to become a Psychiatric Mental Health Nurse Practitioner.

Brittany Bentley, daughter of Jonathan Bentley (Coating Op), graduated from Chariho Regional HS. Brittany will be attending CCRI in the fall to study Arts & Humanities Pathway and plans to pursue a career in Integrated Design.

Adriana Abby, niece of Tina Abby-Cannao (GR Clerk), graduated from Chariho Regional HS. Adriana will be attending Wentworth Institute in the fall to study Architecture and plans to pursue a career focusing on eco-friendliness, sustainability, and renewability.

Screen Printing

Brookwood Finishing has advanced printing capabilities from decorative prints to technical prints for armed services with protective camouflage characteristics. We have a state-of-the-art rotary screen printer capable of

- Wet Printing

- Pigment Printing

- Applying Printed Coatings

Dyeing

Brookwood Finishing has advanced wash ranges for scouring and preparing fabric for atmospheric, pressure and continuous dyeing processes. Sophisticated visual shade matching light sources and computerized color evaluation systems provide for expert shade matching. We have one of the nation’s leading dyeing facilities with the following processing capabilities:

- Jig

- Jet

- Atmospheric Beam

- Pressure Beam

- Pad

Finishing

At our Brookwood Finishing, Rhode Island plant, we have state-of-the-art finishing equipment including pin and clip tenter frames, steam frames, relaxation dryers, calendars, surface finishers and contact heat setting equipment providing us with finishing capabilities such as:

- Water Repellent Finishes

- Dip and Face Finishing

- Wickable Treatments

- Fire Retardant Finishes

- Resin Finishes

- Antimicrobal Treatment

- and more

Coating

Brookwood Finishing has the capability to apply solvent or aqueous-based coatings on state-of-the-art coating lines with multiple coating stations. We have the ability to apply many types of coatings including clear urethane, tapeable, fire retardant, pigmented, breathable, non-ravel, inkable, and antimicrobial, to name a few.

Our capabilities include:

- Handling substrates from 30d nylon to 1050d nylon

- Coating weight applications from two tenths of an ounce to three ounces per square yard

- Single and Double sided coatings

- Widths up to 72″ (62″ for aquaeous based coating applications)

Testing Lab–ISO 9001:2015

Our Lab is qualified to test to ASTM, AATCC, ISO, NFPA, and federal test methods recognized by Military, Consumer, and Industrial customers. These test methods provide analysis of important physical characteristics of performance fabrics including:

Our Lab is qualified to test to ASTM, AATCC, ISO, NFPA, and federal test methods recognized by Military, Consumer, and Industrial customers. These test methods provide analysis of important physical characteristics of performance fabrics including:

- Water Resistance

- Oil Resistance

- Breathability

- Strength of Fabric

- Dimensional Stability

- Flammability

- Colorfastness

- Weather Resistance

- and much more

Research and Development Lab

Brookwood’s Research and Development Lab resides at the Brookwood Finishing facility in Rhode Island. This lab provides a rapid response product development capability. With advanced pilot production dyeing, printing, coating, and finishing lines, we are able to perform multiple trials and analyses of those trials within hours, instead of days, accelerating the ability to develop new products.

Inquiry

Feel free to reach out to us or call our toll-free number at 1-800-426-5468.